A surprisingly large number – from everyday consumer items to critical medical devices and automotive components.

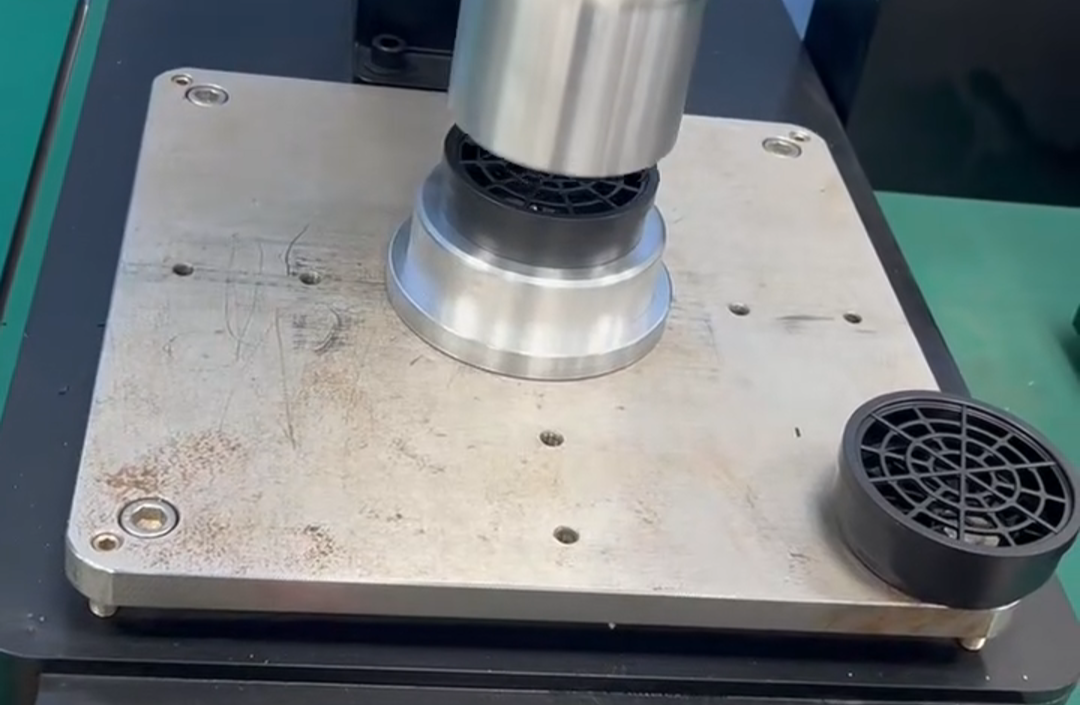

Ultrasonic welding is one of the most efficient and reliable methods for joining thermoplastic parts, creating strong, hermetic seals without adhesives, screws, or solvents. This advanced technique uses high-frequency vibrations to generate frictional heat at the joint interface, melting the plastic just enough to form a permanent molecular bond. The result? Clean, precise, and durable assemblies that meet the highest standards across industries.

The Versatility of Ultrasonic Welding Across Industries

Ultrasonic welding is widely adopted because it delivers fast cycle times, consistent quality, and cost savings. Here’s a look at how extensively it’s used in various sectors:

- Automotive: From instrument panels, door panels, and lamps to air ducts, fluid reservoirs, and light clusters – countless plastic components rely on ultrasonic welding for strong, vibration-resistant bonds.

- Medical Devices: Filters (blood, gas, arterial), face masks, catheters, insulin pumps, and sterile garments are assembled with ultrasonic welding to ensure contamination-free, hermetic seals critical for patient safety.

- Consumer Electronics: Mobile phones, remote controls, computer circuit boards, transformers, capacitors, and storage media like flash drives benefit from precise, damage-free joining of delicate parts.

- Packaging: Blister packs, beverage cartons, food containers, tubes, and sealed pouches achieve airtight, sanitary seals perfect for food, pharmaceuticals, and consumer goods.

- Household Appliances: Washing machines, vacuum cleaners, kitchen appliances, and toys often feature ultrasonically welded housings and components for durability and aesthetics.

- Toys and Consumer Goods: Plastic toys, pacifiers, light balls, and everyday items like folders or photo albums use this method for safe, seamless assembly.

The answer to “how many” is millions – virtually every industry that manufactures plastic products incorporates ultrasonic welding for its speed, cleanliness, and superior bond strength.

Why Choose Ultrasonic Welding?

Key advantages include:

- Fast and energy-efficient process with cycle times under a second

- No consumables like adhesives or fasteners, reducing costs and environmental impact

- Clean, aesthetic joints with no flash or residue

- High reproducibility and process control for consistent quality

- Suitable for both similar and dissimilar thermoplastics

Expert Injection Molding and Post-Processing Services

At Ningbo Chenshen Plastic Industry, we specialize in high-precision injection molding and offer ultrasonic welding as one of our comprehensive post-processing services. From custom mold design to final assembly, we manufacture durable plastic products tailored to your needs, ensuring tight bonds and superior performance in demanding applications.

Ready to bring your plastic product ideas to life with professional injection molding and ultrasonic welding?

Post time: Dec-24-2025