You have a groundbreaking product idea. But in 2025, how do you choose the right way to make it out of plastic?

You have a groundbreaking product idea. But in 2025, how do you choose the right way to make it out of plastic?

The material’s benefits are clear: it’s cost-effective, water-resistant, chemically stable, and can be molded into virtually any shape and color. However, the environmental concerns are equally clear. The industry is evolving, with leading manufacturers adopting sustainable practices like using recycled materials and maximizing energy efficiency. This guide cuts through the complexity. We will help you navigate the key plastic manufacturing processes, detailing the pros, cons, and ideal applications for each—whether you’re creating a one-off prototype or partnering with a mold factory for mass production. A mold factory can help you achieve high-volume production.

Key Takeaways

- Understand plastic types: Thermoplastics can be reshaped and recycled, while thermosets are stronger and heat-resistant but cannot be remolded.

- Choose the right manufacturing method: 3D printing is for quick prototypes, CNC machining is for precise parts, and injection molding is best for making many items.

- Balance cost, volume, and time: High production needs often mean higher initial tool costs but lower costs per item.

- Pick materials carefully: The right plastic affects how well your product works and how much it costs.

- Combine different methods: Using various manufacturing steps together helps make products faster and cheaper.

Understanding Plastic Materials for Product Development

Thermoplastics and Thermosets

When you choose plastics for your product, you first need to understand two main types: thermoplastics and thermosets. Thermoplastics do not form chemical bonds during curing. This means you can remold and recycle them. Thermosets, however, form strong chemical bonds when cured. You cannot remold them. They are generally stronger and more heat resistant. Thermosets keep their strength and shape at high temperatures. They often degrade before melting. Thermoplastics offer high strength and durability. You have more manufacturing options with them. You can also melt them down and recast them at the end of their life. Thermosets offer extreme temperature tolerances and excellent mechanical properties. They are hard, tough, and rigid. They do not melt and you cannot reshape them once set.

| Property | Thermoplastic (e.g., Polypropylene) | Thermoset (e.g., Epoxy) |

|---|---|---|

| Heat Deflection Temperature (HDT) | Low HDT | Exceptionally high HDT |

| Elasticity | More elastic | Less elastic (due to cross-linked, rigid bonds) |

| Toughness | Higher toughness | Lower toughness (due to brittle cross-linked bonds) |

Common Engineering Plastics and Properties

Engineering plastics offer superior mechanical and thermal properties compared to standard plastics. They resist heat better, often working continuously up to 150 °C (300 °F). Each type has unique features. For example, polycarbonates have high impact resistance. Polyamides offer excellent abrasion resistance. You will find other traits like mechanical strength, rigidity, and chemical stability.

Engineering plastics are strong and tough. They resist force without breaking. Think of polycarbonate sheets in helmets. They also absorb energy without fracturing, like ABS in car interiors. They have good wear resistance, important for moving parts. Acetal (POM) and UHMWPE have low friction, making them good for gears. These plastics also maintain their size and shape under different temperatures and humidity levels. Cast nylon and PTFE are great for precision parts. They resist high temperatures. PEEK, for instance, can handle continuous use at 260°C in aerospace parts.

Material Selection for Performance and Cost

Choosing the right plastic involves balancing performance needs with cost. You can save money by using recycled plastics. This also helps the environment. However, you must manage market changes in availability. You should also explore alternative materials like bioplastics. These can offer long-term cost benefits and meet sustainability goals. Always do a full cost-benefit analysis. Consider availability, cost, and any manufacturing changes you need to make.

You might absorb cost increases to keep customers happy. This could reduce your profits. You could also pass costs to consumers. This protects your profit margins but might affect customer loyalty. Evaluating cheaper materials or new suppliers helps control costs while keeping quality high. Managing material costs effectively gives you a competitive edge. You can offer better pricing. Price increases can also lead to negative customer views. Always communicate value and quality clearly. Strategic planning for material cost changes is vital for your business’s long-term success.

Key Manufacturing Processes: From Concept to Scale

You move from design to a physical product using various manufacturing processes. Each method offers unique benefits for different stages of product development. Understanding these processes helps you choose the best path for your plastic product.

3D Printing for Rapid Prototyping and Iteration

3D printing, also known as additive manufacturing, builds objects layer by layer. This method is excellent for rapid prototyping and quickly testing new ideas. You can create complex shapes that are difficult to make with other methods.

3D printing helps you in many ways during product development:

- Concept Validation: You can create a basic model of a new gadget. This helps you assess its overall shape and how easy it is to use.

- Proof-of-Concept Prototype (POC): You can develop a simple version of a new mechanical part. This shows if your idea can actually work.

- Visual Prototypes: You can make models for looking at and showing to others. Fashion designers use these to display new clothing designs.

- Functional Prototypes: You can test how parts and assemblies work. Automotive engineers produce prototypes to test car components in real conditions.

- Engineering/Pre-Production Prototypes: You can create detailed models to test engineering performance. Aerospace companies develop prototypes to check aerodynamics and how strong structures are.

- Aesthetic and Ergonomic Testing: You can evaluate how a product looks and feels. Consumer electronics firms create prototypes to test how comfortable a new device is to hold.

- Engineering Verification: You confirm design details and how well things work before making many products. Engineers produce prototypes to check if mechanical parts fit and work correctly.

- Custom Tools and Fixtures: You can make special tools and parts for manufacturing. Factories use 3D printing to create custom jigs and fixtures for assembly lines.

The main advantage of 3D printing is its speed and flexibility. You can quickly make changes to your design and print a new version. This saves time and money in the early stages. However, 3D printed parts often have visible layers and may not be as strong as parts made with other methods. It is most cost-effective for single parts or very small batches.

CNC Machining for Precision Prototyping and Tooling

CNC (Computer Numerical Control) machining uses computer-controlled tools to remove material from a solid block. This method offers very high precision and excellent surface finishes. You use CNC machining when your prototype needs exact dimensions and smooth surfaces.

CNC machines are very precise. They capture every detail of your design accurately. This is important for prototypes that need complex features or must fit perfectly with other parts. CNC machining can achieve tolerances that are hard to get with other methods. It also gives you smooth surfaces that usually need little extra work. This is good for prototypes that need a high-quality finish for testing or looks.

You can use CNC machines with many plastic materials. This lets you choose materials based on what your prototype needs, like strength, flexibility, or heat resistance. This versatility also allows you to test different materials to find the best one for your final product.

Common plastics compatible with CNC machining include:

- ABS

- Nylon

- Polycarbonate

- PEEK

CNC machining is great for plastic prototype designs with tiny details. It works well for patterns with small curves and tight tolerances. A CNC milling machine can make curves as small as R0.05 mm and keep tolerances as tight as 4 μm. Also, CNC machining gives you a high-quality surface finish. It avoids the layer marks you see in 3D printing. This is helpful for showing off your concepts or ideas clearly.

CNC machines also work with specialized plastic materials that are almost impossible to 3D print. These include:

- PVC

- PEI

- POM

- PEEK

Here are some common plastics you can use with CNC machining and their benefits:

| Plastic Type | Key Qualities | Common Uses/Benefits |

|---|---|---|

| Acrylic (PMMA) | Lightweight, clear, transparent, impact-resistant, smooth finishes | Display cases, signage, where visibility is essential |

| Polycarbonate (PC) | Strong, durable, resistant to breakage, rigid | Protective covers, safety goggles |

| Nylon (PA) | Strong, flexible, resists wear and abrasion | Gears, bearings, parts with friction/stress |

| ABS (Acrylonitrile Butadiene Styrene) | Rigid, impact-resistant, easy to machine and finish | Automotive parts, consumer goods, electronic housing |

| Delrin (Polyoxymethylene, POM) | Strong, low-friction, stiff | Gears, fasteners, wear strips, precision engineering parts |

| PTFE (Polytetrafluoroethylene) | Low friction, chemical resistance, soft | Non-stick applications, parts in contact with harsh chemicals |

CNC machining is ideal for creating high-precision prototyping and durable tooling. It is more expensive than 3D printing for single parts but offers superior quality and material options.

Vacuum Casting for Realistic Prototyping and Small Batches

Vacuum casting is a method you use to create high-quality, realistic prototypes and small batches of parts. It uses a silicone mold made from a master model, often created by 3D printing or CNC machining. You pour liquid resin into this mold under vacuum conditions. This removes air bubbles and ensures a perfect reproduction of the master model.

Vacuum casting offers several advantages for your product development:

- Realistic Prototypes: You can produce parts that closely mimic the look, feel, and mechanical properties of final production parts. This is great for testing how a product will perform in real-world conditions.

- Material Versatility: A wide range of materials are available to simulate production plastics. These include:

- ABS-like polyurethane resins: These offer good impact resistance and keep their shape well. They are suitable for consumer electronics housings.

- PC-like polyurethane resins: These provide high strength and heat resistance. They are ideal for functional prototypes needing toughness.

- PP-like polyurethane resins: These are known for excellent resistance to repeated bending. You often use them in snap-fit automotive prototypes.

- Epoxy systems: These have high stiffness and resist chemicals. They are suitable for structural or decorative parts.

- Specialty silicones: You use these for flexible or rubber-like parts for soft-touch applications.

- Acrylic (PMMA)-like resins: These are clear and resist UV light well. You use them in lighting and lenses.

- Silicone and TPU-like materials: These provide flexibility, elasticity, and temperature resistance. They are good for seals, gaskets, and medical devices.

- Cost-Effective for Small Batches: It is more economical than injection molding for producing 20 to 100 parts. You avoid the high cost of hard tooling.

The lead times for vacuum casting are generally quick. They typically range from 7 to 15 business days, depending on how complex your part is and how busy the supplier is. For a medium batch of 20–30 parts, you can complete the process within 10 days.

Here is a quick look at vacuum casting factors:

| Factor | Vacuum Casting |

|---|---|

| Lead Time | 10–20 days |

| Material Choice | Polyurethane, elastomers, TPE, etc. |

While vacuum casting provides excellent surface finish and material properties, the silicone molds wear out after a certain number of cycles. This makes it unsuitable for very high-volume production.

Thermoforming for Cost-Effective Large Parts

Thermoforming is a process where you heat a plastic sheet until it becomes pliable. Then, you stretch it over a mold and hold it in place until it cools and takes the mold’s shape. This method is excellent for creating large, relatively thin-walled plastic parts. Think of refrigerator door liners, bathtubs, or vehicle dashboards.

You gain significant cost advantages when you choose thermoforming, especially for larger parts.

- Lower Tooling Investment: Thermoforming tools typically cost much less than those for other methods like injection molding. You can expect to pay $5,000 to $50,000 for thermoforming tools. Injection molding tools, however, often start at $20,000 and can go well over $150,000. This difference significantly reduces your financial risk and initial capital spending.

- Faster Time-to-Market: You can get thermoforming tooling ready in 1 to 8 weeks. Injection molding tooling takes much longer, usually 12 to 16 weeks. Production also starts faster with thermoforming, often within 1 to 2 weeks after tool approval. This means you can generate revenue sooner and respond to market demands more quickly.

- Economic Flexibility: You can use prototype tooling made from wood, ceramic, or machinable boards. This allows you to test designs and materials with minimal investment. You can make design changes before you commit to full production tooling.

- Advantage for Large Parts: For parts larger than two feet square, thermoforming often remains economically viable even at higher production volumes. Injection molding faces much higher tooling costs and requires larger presses for such sizes. It also involves more complex material handling.

- Hidden Economic Benefits: You can also benefit from lower shipping costs because thermoformed components are lighter. You might also reduce secondary operations and assembly costs by consolidating parts.

Thermoforming is a clear choice when your main concern is the initial cost for large parts. Its tooling is significantly more affordable compared to injection molding. However, thermoformed parts may not have the same level of precision or intricate detail as injection molded parts.

Injection Molding for Mass Production

Injection molding is a highly precise manufacturing process. You inject molten plastic material into a mold cavity. The plastic then cools and solidifies into the desired part. This method is the workhorse of mass production for plastic products. It creates parts with excellent surface finish and tight tolerances.

You will find injection molding ideal for high-volume production runs. High production volumes directly influence your costs. When you produce a large quantity of parts, your per-unit cost decreases. This happens because you spread the initial setup expenses, like mold creation and machine calibration, across many more units. Conversely, low-volume production often results in higher per-unit costs. This is due to more frequent setup changes and smaller batch sizes.

Injection molding tools can vary greatly in cost. Simple parts using a Multi-Unit Die (MUD) frame might cost $15,000. Large, complex geometries requiring high tonnage machines can exceed $500,000.

Consider these factors when deciding between prototyping and on-demand manufacturing with injection molding:

| Feature | Prototyping | On-Demand Manufacturing |

|---|---|---|

| Objective | Validate design | Flexible on-demand production of end-use parts |

| Best When | Lifetime volumes likely below 2,000 parts; affordable tooling entry point important; part production needed for 1 year or less | Lifetime volumes exceed 2,000 parts; lower part price critical; part production needed for several years |

| Mold Price | Lower | Higher |

| Part Price | Higher | Lower |

Injection molding offers unmatched repeatability. It produces identical parts consistently. You can use a vast range of plastic materials with this process. This includes thermoplastics and some thermosets. While the initial tooling investment is high, the low per-unit cost in mass production makes it very economical for large quantities.

Extrusion for Continuous Profiles

Extrusion is a continuous manufacturing process. You melt plastic material and push it through a die. This die shapes the molten plastic into a continuous profile. Think of it like squeezing toothpaste from a tube. This method is highly efficient for producing long, uniform shapes.

You commonly produce many plastic profiles using extrusion:

- Pipes and Tubing: You see these in plumbing, irrigation, and electrical conduits. Materials like PVC, HDPE, and PEX are common.

- Profiles and Channels: These include window and door frames, trim, weatherstripping, and decorative moldings.

- Packaging Materials: This process creates plastic films and sheets for bags, pouches, and shrink wraps.

- Wire and Cable Insulation: You use extrusion to provide electrical insulation and protection for wires.

- Filaments and Fibers: This includes materials for 3D printing, textiles, and reinforcement. PLA, ABS, nylon, and PET are common choices.

- Sheet and Film Products: These are used in packaging, construction, signage, and automotive interiors. You can further process them into trays, containers, or dashboards.

However, plastic extrusion does have some limitations:

- High Initial Setup Costs: You need a significant investment for extruders, dies, and downstream equipment. This can be a barrier for small-scale production, especially for specialized applications.

- Product Limitations: Extrusion works best for continuous profiles with a constant cross-section. It is not ideal for intricate or complex shapes with varying cross-sections. This limits its versatility for certain designs.

- Size Variation: Plastic expands significantly due to heat during the process. This leads to deviations from your intended dimensions. It is difficult to accurately predict the extent of these changes. This differs from the precise tolerances you can achieve with metal.

Extrusion is a cost-effective method for producing large volumes of consistent, long plastic shapes. You will find it indispensable for products like pipes, films, and window frames.

Strategic Process Selection: Volume, Cost, and Lead Time

Choosing the right manufacturing process for your plastic product involves a careful balancing act. You must consider how many units you need, how much money you can spend, and how quickly you need to get your product to market. These three factors—volume, cost, and lead time—are critical for making smart decisions.

Volume and Scale Considerations

Your production volume directly influences which manufacturing process you should choose. Some processes have high tooling costs but offer very low costs per part when you produce many units. Other methods have minimal setup costs but result in higher prices for each individual part. You need to ask yourself key questions: What is your annual manufacturing volume? Is this a one-off production run, or will you produce regularly? Do you need flexibility in your production volume?

Production volume is a major factor. Injection molding, for example, has high upfront costs. This makes it economical for high-volume runs but not practical for prototyping. In contrast, processes like CNC machining have lower initial costs. However, they can have higher per-part costs, especially if they involve manual labor. You must balance your production volume with cost-effectiveness.

Here is a breakdown of common processes and their suitable production volumes:

| Process | Production Volume Range | Cost-effectiveness | Tooling Costs | Per-Unit Costs | Other Features |

|---|---|---|---|---|---|

| Injection Molding | High-volume (10,000+ parts) | High ROI for large volumes | High | Low | Complex geometries, tight tolerances, wide material selection |

| Thermoforming | Medium to high-volume (1,000-10,000 parts) | Cost-effective for large, thin-walled parts | Moderate | Moderate | Large parts, good for enclosures and packaging |

| Blow Molding | High-volume (10,000+ parts) | Cost-effective for hollow parts | High | Low | Hollow parts (bottles, containers), various shapes and sizes |

| Rotational Molding | Low to medium-volume (100-10,000 parts) | Cost-effective for large, hollow, seamless parts | Low | Moderate | Large, hollow, seamless parts, uniform wall thickness |

| Extrusion | High-volume (continuous production) | Very cost-effective for continuous profiles | Moderate | Low | Continuous profiles (pipes, tubes, sheets), consistent cross-section |

| 3D Printing (Additive Manufacturing) | Low-volume (prototyping, custom parts, 1-100 parts) | High per-part cost, but low setup | Low | High | Complex geometries, rapid prototyping, customization, no tooling required |

| CNC Machining | Low to medium-volume (prototyping, precision parts, 1-1,000 parts) | High precision, good for small batches | Low | High | High precision, excellent surface finish, good for functional prototypes |

| Vacuum Casting (Urethane Casting) | Low-volume (prototyping, small batches, 1-50 parts) | Cost-effective for small series of high-quality prototypes | Low | High | High-quality prototypes, good surface finish, various material properties |

Cost Implications: Tooling vs. Unit Price

You must carefully evaluate the cost implications of tooling versus the unit price of each part. This decision significantly impacts your overall budget.

For plastic injection molding, tooling costs can vary widely:

- Small, simple molds might cost you $1,000 to $5,000.

- Medium-sized, moderately complex molds typically range from $5,000 to $25,000.

- Large, complex molds can cost $25,000 to over $100,000.

The cost per part also changes with complexity and volume:

- Simple, small parts might cost $0.10 to $1.00 each.

- Parts with moderate complexity usually cost $1.00 to $5.00 each.

- Large or complex parts can be $5.00 to $50.00 each.

Your production volume heavily influences the estimated cost per part:

- For 1,000 units, you might pay $5.00 to $50.00 per part.

- At 10,000 units, the cost drops to $1.00 to $5.00 per part.

- For 100,000 units, you could see costs of $0.10 to $1.00 per part.

- If you produce 1,000,000 or more units, the cost can be as low as $0.05 to $0.50 per part.

When you compare different methods, you see clear cost differences:

- 3D Printing: This method is best for prototyping and low-volume production. However, it becomes expensive for large production runs.

- Injection Molding: This process is highly cost-effective for mass production.

- CNC Machining: This offers higher precision but is more expensive per unit. This is due to material wastage and longer machining times.

- Injection Molding: This is better for high-volume plastic part production.

- Blow Molding: This method suits hollow parts like bottles.

- Injection Molding: This is ideal for solid and complex components.

For large-scale production of plastic parts, injection molding generally remains your most economical option.

Lead Time and Time-to-Market

The manufacturing process you choose significantly impacts your overall lead time. This affects how quickly you can get your product to market.

Injection molding involves lengthy design and tooling periods. This often takes several months. However, once you establish the tooling, it can become the fastest option for production. In contrast, additive manufacturing, such as Carbon Digital Light Synthesis or HP Multi Jet Fusion, produces end-use parts much more quickly. This allows for faster prototyping and immediate production without needing to retool.

Several factors can help you reduce lead times:

- Automation and robotics: These increase production efficiency, minimize human error, and reduce lead times.

- Lean manufacturing: This minimizes waste and maximizes value. It reduces the time a part takes to move through production by eliminating non-value-adding activities.

- In-house mold shops: These allow for mold maintenance, reducing downtime and enabling quick repairs.

- Strong supplier relationships and material inventory: These prevent delays due to supply chain disruptions and material availability issues.

- Stocking programs and Vendor Managed Inventory (VMI): These streamline inventory management, improve forecasting, and accelerate order processing. This leads to reduced lead times.

- Integrated services: Combining services like CNC machining and secondary operations with a single vendor reduces your time to market.

You should also understand the typical timeframes for mold development:

- Plastic injection molds usually require 3 to 4 correction loops. They also need 1 to 2 months for repairs and maturation.

- The manufacturing company’s workload can extend lead times.

- A simple mold might take 4 to 6 weeks. A complex mold could take 6 to 8 weeks.

- An aluminum prototype mold can take 2 to 3 weeks.

- Innovative manufacturing technologies, like automation and robotics, help shorten lead times.

- High-demanding parts or extensive quality assurance and quality control checks can prolong lead times.

- Research and development (R&D) involvement in testing manufacturing methods, new materials, or designs will also affect your lead time.

Overall, molds are typically completed within 3 to 5 months. Prototype molds usually take 1 to 3 months.

Material Requirements and Product Performance

Choosing the right plastic material is crucial for your product’s success. It directly impacts how well your product performs and how long it lasts. Before you select a material, you must consider several key design factors.

First, think about your product’s performance requirements. What forces and stresses will the part endure after you install it? Next, consider the dimensional attributes. What specific size, shape, and surface qualities does your product need? Finally, determine your target cost. How can your budget maximize performance without overspending?

Material selection involves answering specific questions about desired performance characteristics and environmental stressors:

- Will the part experience significant wear, or is it a structural component?

- What is the operational temperature range for your product?

- What environmental stressors, such as extreme temperatures, abrasive forces, corrosive chemicals, or sunlight, do you need to consider?

- What are the minimum strength requirements for your part?

- Are there specific appearance requirements like color or transparency?

Understanding the fundamental types of plastics helps you make informed decisions. Plastics fall into two main categories: thermosets and thermoplastics. Thermosets, once you form them, cannot be re-melted and reformed. They generally require less heat and pressure to form. They offer high heat and chemical resistance, but you typically cannot recycle them. Thermoplastics, on the other hand, you can melt and remold. They require more heat and pressure during their initial formation. The final properties of parts made from thermoplastics vary significantly based on the specific material you choose.

Different resin grades offer varied performance characteristics:

- Glass or carbon reinforced: You use these for superior strength, stiffness, and dimensional stability.

- Wear grades (with graphite and PTFE): These provide maximum wear resistance and low friction.

- Unfilled or glass-reinforced: You choose these for superior thermal or electrical insulation.

- Non-reinforced: These offer the best chemical resistance and excellent fatigue resistance at low stress levels.

You have a wide array of resin types, each with unique benefits:

| Resin Type | Benefits |

|---|---|

| POM or Acetal (Polyoxymethylene) | Tough, stiff, hard, strong; good lubricity and resistance to hydrocarbons/organic solvents; good elasticity, slippery; low creep; great fatigue properties. |

| PMMA or Acrylic (Polymethyl Methacrylate) | Good optical properties, high gloss, scratch resistant; low shrink, less sink in geometries with thin and thick sections. |

| ABS (Acrylonitrile butadiene styrene) | Tough, impact- and chemical-resistant; low shrink, high dimensional stability; inexpensive. |

| HDPE (High-density polyethylene) | Tough, impact- and chemical-resistant; high shrink, low dimensional stability; inexpensive; density less than water (floats). |

| PC (Polycarbonate) | Strong, extremely impact resistant; low shrink, good dimensional stability and heat resistance; accepts high cosmetic finishes well. |

| ABS/PC | Strength, heat and low-temperature resistance; improved processing. |

| PP (Polypropylene) | Inexpensive; higher impact resistance in some grades; wear resistant, flexible with high elongation; resistant to acids and bases; density less than water (floats). |

| Polystyrene (PS) | High optic clarity, good electric insulator. |

| PEEK (Polyether Ether Ketone) | High-temperature, high-performance, flame retardant; excellent strength and dimensional stability, good chemical resistance. |

| PEI or Ultem (Polyetherimide) | High-temperature, high-performance, flame retardant; excellent strength and dimensional stability, good chemical resistance. |

| PPSU (Polyphenylsulfone) | High-temperature tolerance, dimensionally stable, high toughness; resistance to radiation sterilization, alkalis, and weak acids. |

| PA (Aliphatic Polyamides) | Wide variety; high strength and temperature tolerance when reinforced; chemically resistant except to strong bases or acids. |

| PPA (Semi-aromatic Polyamides) | Less susceptible to moisture than aliphatic polyamides. |

| PBT (Polybutylene Terephthalate) | Good electrical properties for power components and automotive applications; moderate to high strength depending on glass fill; good resistance to fuels, oils, fats, and many solvents; low creep. |

| PET (Polyethylene Terephtalate) | Stiffer and higher melting point than PBT. |

| LCP | Very easy flowing, good chemical resistance, high upper use temp, good electrical properties, low thermal expansion. |

| PPO | Good electrical insulator, hot water- and steam-resistance. |

| PPS | Very good chemical resistance, high upper use temp, great electrical properties. |

You also have a range of materials with specific properties for various applications:

| Material | Properties |

|---|---|

| ABS-like | General purpose, strength |

| Ceramic-like | Strength, stiffness, temperature resistance |

| Digital Photopolymer | Flexibility |

| PA11, PA12 (nylon) | Durability, dimensional stability |

| PC-like | Transparency, stiffness |

| Polypropylene | Flexibility, chemical resistance, dimensional stability |

| PP-like | Flexibility, transparency, durability |

| TPU | Flexibility, impact resistance, wear resistance |

| True Silicone | Temperature resistance, wear resistance, flexibility, moisture resistance |

Design Complexity and Geometric Constraints

The complexity of your product’s design significantly impacts its manufacturability, cost, and the risk of errors. Geometric complexity refers to the level of detail in shapes and parts. Complex shapes often require specialized tools and longer machining times. This increases the risk of manufacturing errors and defective products. You can reduce production costs and improve product quality by simplifying geometries. For example, eliminate complex shapes, fillets, and R radii where possible.

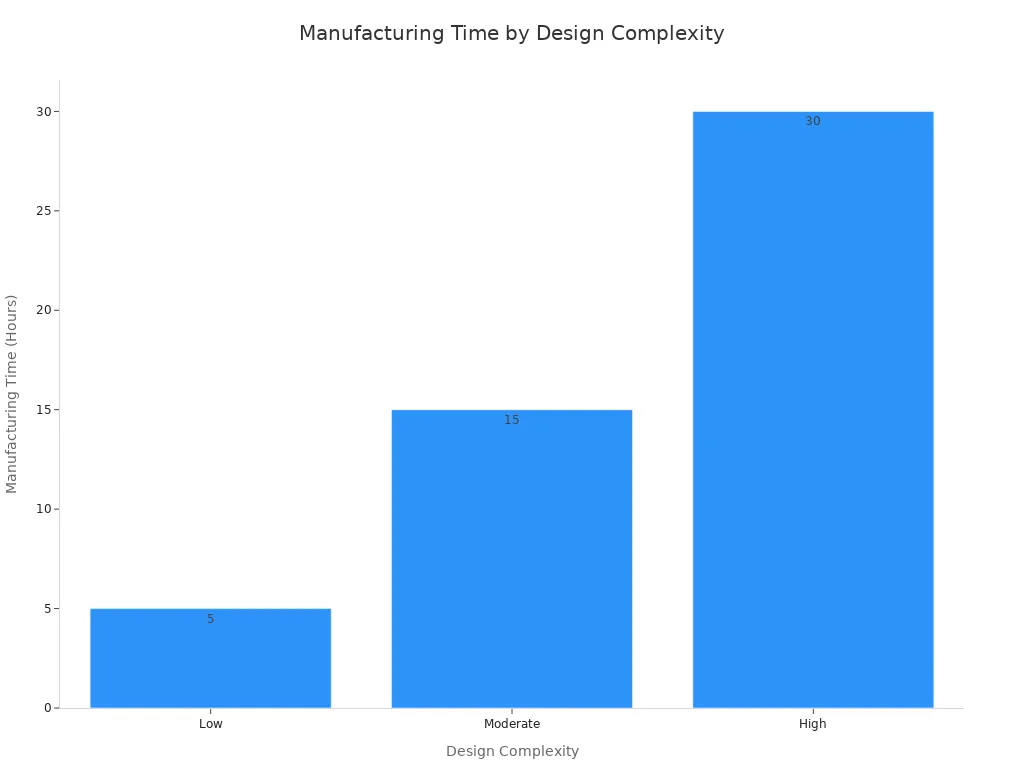

Consider how design complexity affects manufacturing time and cost:

| Design Complexity | Typical Manufacturing Time (Hours) | Cost Implications |

|---|---|---|

| Low | 5 | Low |

| Moderate | 15 | Medium |

| High | 30 | High |

You can visualize the impact of complexity on manufacturing time:

Tolerance and precision also play a crucial role. Tight tolerances demand more complex equipment, additional control steps, and longer working hours. This leads to higher costs. You can lower manufacturing expenses and reduce the likelihood of flawed products by designing within allowable deviations. Furthermore, minimizing the part count reduces assembly operations, handling, storage, and inventory costs. This contributes to overall efficiency and cost reduction.

To optimize your design for manufacturing:

- Minimize part count by eliminating or combining components to reduce manufacturing costs.

- Optimize parts for your chosen manufacturing process, such as plastic injection molding, casting, or stamping. This ensures manufacturability and reliability, reducing production errors.

- Design for cost reduction by considering alternative materials, manufacturing processes, or tooling options.

- Review the cost implications of single part complexity versus assembly time for multi-part assemblies.

- For plastic injection molded parts, ensure uniformity and consistency in wall thickness, draft, ribs, and texture.

Leading manufacturers widely adopt plastic injection molding for custom plastic parts. This is due to its consistency in wall thickness, its ability to maintain close tolerances, and its optimal balance of functionality and costs. This method offers maximum flexibility for creating products with complex designs. It is a superior and popular technique that balances design requirements, product applicability, quantity needs, and manufacturing time for functional, durable, and cost-effective plastic parts.

Integrating Processes for Optimal Product Development

You often need to combine different manufacturing methods to bring a plastic product from concept to market. This strategic integration helps you optimize efficiency, manage costs, and accelerate your development timeline.

Combining Prototyping Methods for Efficiency

You do not have to rely on just one method for prototyping. You can combine different techniques to achieve the best results. For example, you can begin with 3D-printed models. These help you quickly validate the form and fit of your design. After this initial validation, you can transition to vacuum casting. This method produces higher quality prototypes or small batches. It gives you parts that look and feel more like the final product. A custom automotive parts manufacturer successfully combined 3D printing with CNC finishing. This hybrid approach produced highly accurate dashboard prototypes. This allowed them to show near-production-quality samples to clients. This optimized their review process. This integration of hybrid manufacturing techniques leverages the precision of subtractive methods with the speed of additive manufacturing. This leads to optimized efficiency in prototype development.

Transitioning from Prototyping to Mass Production

Moving from prototyping to mass production requires careful planning. First, you must focus on Design for Manufacturability (DFM). This initial phase optimizes your product design for efficient mass production. You consider material selection, wall thickness, and draft angles. You also simplify designs and standardize components. Involving your injection molder early is crucial here. As your design matures, your prototypes should increasingly mimic production methods. This involves using techniques like CNC machining, rapid injection molding, and 3D printing. These validate the design’s practicality for mass production. Prototype injection molding is especially valuable for testing with final materials and processes. Once your design is stable, you develop your production process. This includes creating tooling, designing assembly lines, and setting up quality control systems. You will face technical challenges like maintaining dimensional consistency and managing tool wear. Logistical challenges include supplier dependability and inventory forecasting. Partnering with manufacturing experts and applying DFM principles helps you navigate these hurdles.

Strategic Use of Injection Molding for Scale

Injection molding offers significant strategic advantages when you need to scale plastic product manufacturing. It is highly cost-effective for high volumes. Your initial mold costs are offset by efficient production. This leads to much lower per-unit costs for large quantities. This allows you to offer competitive prices and maintain profit margins. Injection molding also provides versatility in design and materials. It accommodates complex designs and a wide range of materials. This enables you to create diverse products with specific properties and aesthetic qualities. You can even use multiple materials and colors in a single mold. The process also reduces waste material. It uses only the necessary amount of plastic. This lowers costs and reduces your carbon footprint. Many manufacturers also use recyclable materials. Finally, injection molding offers excellent scalability for business growth. You can easily ramp up production to meet increased demand. You can run multiple molds simultaneously. This adaptability supports your long-term growth strategies and market expansion.

Future Outlook: Innovations in Plastic Manufacturing for 2025

You will see exciting changes in plastic manufacturing by 2025. New materials and smart technologies will shape the industry. Sustainability will also become a top priority.

Advanced Materials and Composites

Innovations in materials will push boundaries. Nanotechnology will play a big role. You will see carbon nanotubes and graphene integrated into composites. These materials will offer better strength, heat stability, and electrical conductivity. They are perfect for products needing extreme durability and light weight. Additive manufacturing, or 3D printing, also helps create complex shapes. This reduces waste and uses materials efficiently. The future includes advanced composites, nanotechnology, and renewable bio-composites. You will also find a focus on sustainable materials. These include thermoplastics, bio-based UPR resin, and recycled fibers (rCF). Manufacturers are developing thermoplastic matrices reinforced with bio-based carbon fibers. They also use bio-based thermosetting epoxy resins with bio-based carbon fibers. This helps achieve sustainability in CFRPs.

Automation and Industry 4.0 Integration

Automation and Industry 4.0 will transform how you make plastics. The Internet of Things (IoT) connects machines and sensors. This collects real-time data. You can monitor equipment and materials. This helps with predictive maintenance and reduces downtime. Artificial Intelligence (AI) and Machine Learning analyze this data. AI predicts defects and suggests optimal machine settings. This improves product quality and molding precision. Big Data Analytics processes large datasets. This helps you understand production trends and make better decisions. Robotics and automation handle repetitive tasks. They improve precision and speed. Cyber-Physical Systems integrate physical processes with digital control. This ensures consistent quality and efficiency. These technologies boost productivity, improve quality, and cut costs. They also offer flexibility for custom products.

Sustainability and Circular Economy Practices

Sustainability will guide plastic manufacturing. You will see more mechanical recycling. This reprocesses plastic waste into new products. Chemical recycling breaks plastics into molecular components. This uses processes like pyrolysis. Bio-based and biodegradable plastics will also become common. These come from renewable resources. Extended Producer Responsibility (EPR) will make manufacturers manage product end-of-life. This promotes sustainable design. Deposit-refund schemes will encourage you to return plastics for recycling. Design for circularity will make products last longer and be easier to repair or recycle. Digital and smart waste management will use AI-driven sorting and blockchain technology. AI-integrated robotic arms will precisely sort items. Blockchain technology will track plastics from production to disposal. This ensures transparency. Mobile apps will guide you on waste disposal and offer recycling incentives. These practices reduce waste and promote a circular economy.

Your informed process selection drives success in plastic product development. You must balance innovation, cost, and market demands. This is crucial for your product’s journey. Prepare for the evolving landscape of plastic manufacturing in 2025. New materials and smart technologies will shape your future. Embrace these changes to stay competitive.

FAQ

What is the main difference between thermoplastics and thermosets?

Thermoplastics melt and reshape. You can recycle them. Thermosets form permanent bonds. They do not melt once cured. They offer higher heat resistance.

When should you use 3D printing versus injection molding?

Use 3D printing for rapid prototyping and low-volume custom parts. It has low setup costs. Choose injection molding for mass production. It has high tooling costs but very low per-unit costs for large quantities.

How does material selection impact product performance and cost?

Material choice directly affects product strength, durability, and environmental resistance. You balance performance needs with cost. Recycled or bioplastics can offer long-term savings and meet sustainability goals.

What are the benefits of integrating different manufacturing processes?

Combining methods optimizes efficiency. You manage costs better. For example, you can use 3D printing for initial concepts. Then, you move to vacuum casting for realistic prototypes. This accelerates your development timeline.

Post time: Nov-19-2025

![IMG_20251119_154458[1]](https://www.ningboplastic.com/uploads/IMG_20251119_1544581.jpg)