In 2025, sourcing custom plastic injection molding from China remains one of the most cost-effective ways to produce high-quality parts at scale. However, many international buyers struggle with inaccurate quotes that lead to unexpected costs, delays, and rework. This comprehensive guide will help you prepare effectively to receive precise, reliable quotations every time.

China’s injection molding industry excels in producing a wide range of products, including plastic bottle caps and closures, automotive plastic components like dashboards and gears, packaging containers and storage crates, medical device housings, and countless consumer and industrial parts. With proper preparation, you can leverage China’s advantages—competitive pricing, advanced machinery, and experienced engineers—while minimizing risks.

Whether you’re a startup prototyping new designs or an established company scaling production, getting an accurate quote is the foundation of a successful project. Let’s dive into why preparation is key and how to do it right.

Why Thorough Preparation Leads to Accurate Quotes

Many buyers send vague inquiries like “quote for plastic part” and end up with wildly varying responses. Manufacturers then make assumptions about materials, tolerances, or volumes, resulting in quotes that don’t reflect reality.

Common issues from poor preparation include:

- Hidden costs emerging later (e.g., mold modifications, higher-grade materials, or expedited tooling)

- Delayed projects due to back-and-forth clarifications

- Inability to compare quotes fairly between suppliers

- Overpaying or receiving suboptimal designs

In contrast, a detailed request allows manufacturers to:

- Provide precise cost breakdowns (tooling vs. per-unit pricing)

- Offer valuable suggestions for cost reduction or improved manufacturability

- Respond quickly—often within 24-48 hours

- Include free value-added services like Design for Manufacturability (DFM) analysis

Investing time upfront saves money and headaches down the line.

Essential Information to Include in Your Quote Request

The more specific you are, the better the quote. Here’s a detailed checklist:

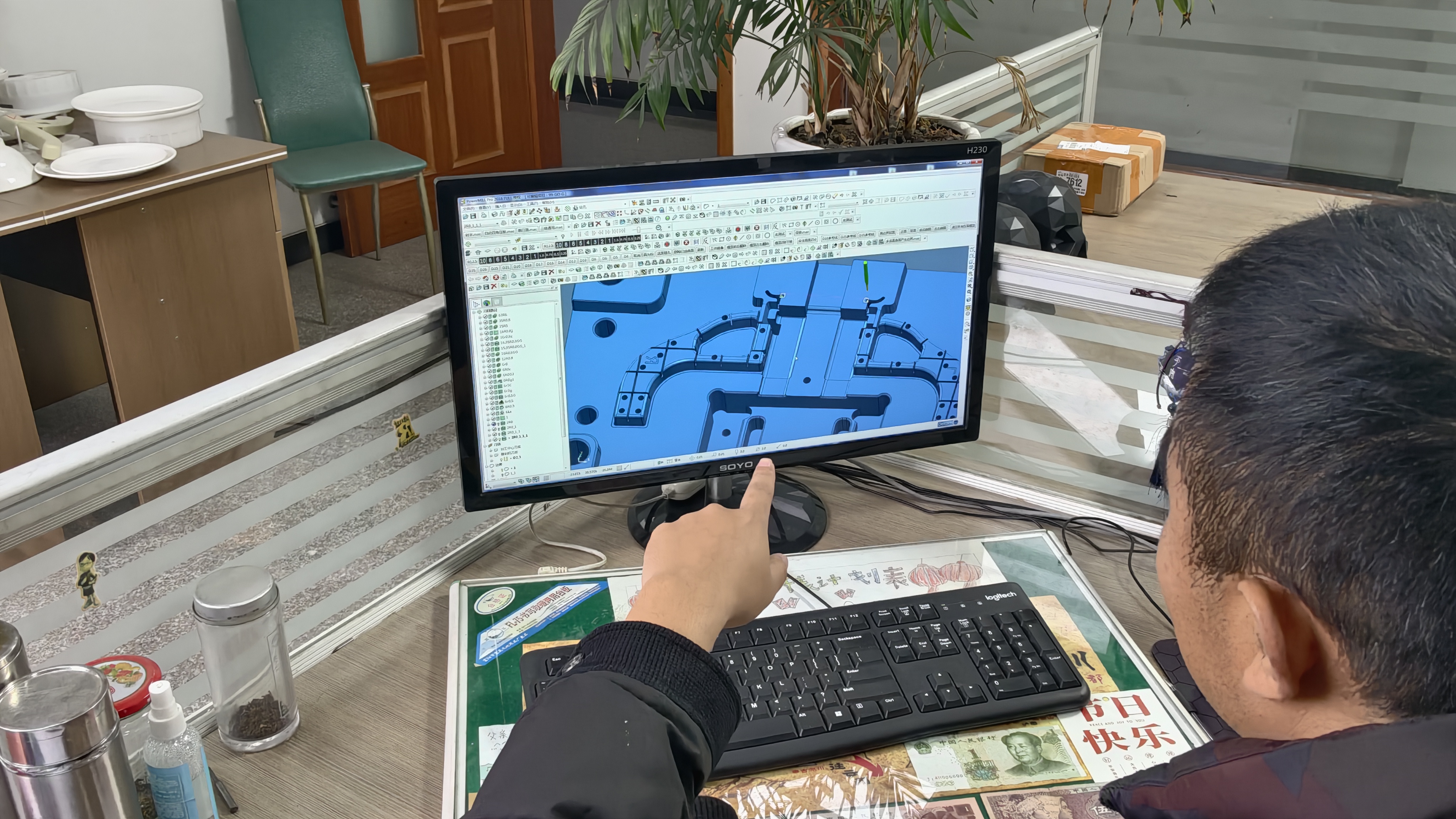

1. 3D CAD Files and 2D Technical Drawings

These are the cornerstone of any accurate quote. Provide files in neutral formats such as STEP (.stp), IGES (.igs), Parasolid (.x_t), or native formats like SolidWorks or Pro/E if possible.

Include detailed 2D drawings showing:

- Critical dimensions and geometric tolerances (GD&T)

- Wall thicknesses, draft angles, and radii

- Locations of parting lines, ejector pins, and gates (or let the manufacturer suggest)

If your design isn’t finalized, share what you have—many factories offer design assistance.

2. Detailed Part Specifications

Specify everything that affects cost and feasibility:

- Material: Common options include PP (polypropylene) for bottle caps, ABS or PC/ABS for automotive parts, HDPE for containers, or medical-grade resins like polycarbonate for housings. Mention additives (UV stabilizers, flame retardants, glass-filled).

- Surface Finish: SPI standards (A-1 polished, B-2 matte, C-3 textured) or specific textures like mold-tech.

- Color: Pantone or RAL codes; masterbatch or pre-colored resin.

- Tolerances: General (±0.1mm) vs. tight (±0.02mm)—tighter means higher cost.

- Special Features: Threads, undercuts, inserts, overmolding, or living hinges.

3. Production Volume and Timeline Requirements

Volume dramatically impacts pricing:

- Low-volume (1,000-10,000 pieces): May use aluminum tooling or higher per-unit costs.

- High-volume (100,000+): Steel molds with multi-cavities for lower unit prices.

Provide estimated annual usage (EAU) and any ramp-up plans. Also state desired lead times for tooling (typically 4-8 weeks) and production start.

4. End-Use Application and Performance Requirements

Tell the manufacturer how the part will be used. For example:

- Food-contact bottle caps need FDA-compliant materials.

- Automotive parts require impact resistance and heat tolerance.

- Medical housings demand biocompatibility and sterilization compatibility.

This helps them recommend the best material and process.

5. Additional Requirements and Secondary Operations

- Post-molding operations: Pad printing, ultrasonic welding, assembly, packaging.

- Certifications: ISO 9001, ISO 13485 (medical), IATF 16949 (automotive), RoHS, REACH.

- Quality standards: PPAP, FAI reports, or specific inspection criteria.

- If no CAD: Send physical samples or sketches for reverse engineering.

Step-by-Step Process to Request and Evaluate Quotes

- Prepare your documentation: Compile all files and specs into a clear RFQ package.

- Identify reputable manufacturers: Look for ISO-certified factories with experience in your industry and good English communication.

- Submit your RFQ: Use the factory’s online form or email—attach files and include a cover letter summarizing key points.

- Request DFM feedback: Professional factories provide this free to highlight potential issues and optimizations.

- Review responses carefully: Compare breakdowns of mold cost, unit price, sampling (T1 trials), shipping, and payment terms (e.g., 30% tooling deposit).

- Follow up: Ask about mold life guarantees, maintenance, and quality assurance processes.

- Negotiate and confirm: Discuss volume-based discounts or payment schedules.

Common Mistakes That Lead to Inaccurate Quotes

- Omitting volume information—forces manufacturers to guess, leading to high “safe” pricing.

- Not specifying tolerances or surface finishes—results in default assumptions.

- Comparing quotes apples-to-oranges (e.g., one includes DFM, another doesn’t).

- Skipping sample approval (T1 trials) before full production.

- Ignoring intellectual property protection—ensure NDA agreements.

- Rushing without verifying factory capabilities through references or audits.

Ready to Receive Your Accurate Quote?

At Ningbo Chenshen Plastic Industry Co., Ltd. (ningboplastic.com), we have over 15 years of experience delivering precision custom injection molding solutions for bottle caps, automotive components, packaging containers, medical parts, and more.

Our team provides free DFM analysis, rapid tooling, strict quality control, and responsive English support to ensure your project succeeds from quote to delivery.

Post time: Dec-29-2025