In the competitive landscape of 2026, the automotive sector is undergoing a radical weight-reduction phase. For Tier-1 suppliers, replacing traditional die-cast aluminum and stamped steel with high-performance thermoplastics is no longer just about cost—it’s about meeting stringent EV range targets and Euro 7 emission standards.

1. Identifying High-Potential Conversion Candidates

Not every metal part is a candidate for conversion. However, modern engineering resins have opened doors for components previously thought to require metal for structural integrity. Key candidates in 2026 include:

- Structural Brackets & Housings: Moving from die-cast aluminum to 30-50% glass-filled PA66.

- Fluid Handling Systems: Utilizing PPS or PPA for high-temperature coolant pipes and oil pans.

- EV Battery Components: Using flame-retardant (UL94-V0) plastics for cell spacers and busbar covers.

2. Advanced Material Science: Beyond Standard Resins

Successful conversion hinges on selecting materials that mimic metal’s mechanical properties while offering polymer advantages.

| Material Property | Plastic Advantage | Automotive Benefit |

|---|---|---|

| Tensile Strength | Carbon-fiber reinforced PEEK/PA | Replaces heavy structural steel |

| Thermal Stability | Continuous use temps up to 240°C | Engine-room and turbo applications |

| Impact Resistance | Modified Elastomers (TPE/TPV) | Crash-safe exterior body panels |

3. The DFM (Design for Manufacturing) Advantage

The greatest cost-saving in 2026 comes from Assembly Consolidation. Where metal requires welding, fastening, and multiple stamps, injection molding allows us to integrate threads, snaps, and living hinges into a single shot. This reduces the Bill of Materials (BOM) and eliminates dozens of potential failure points in the supply chain.

4. Supply Chain Resilience & Sustainability

Transitioning to plastic also supports “Circular Economy” mandates. Many 2026 engineering polymers are now available in PCR (Post-Consumer Recycled) grades that maintain 95% of virgin material strength, helping Tier-1 suppliers meet green procurement targets without sacrificing safety.

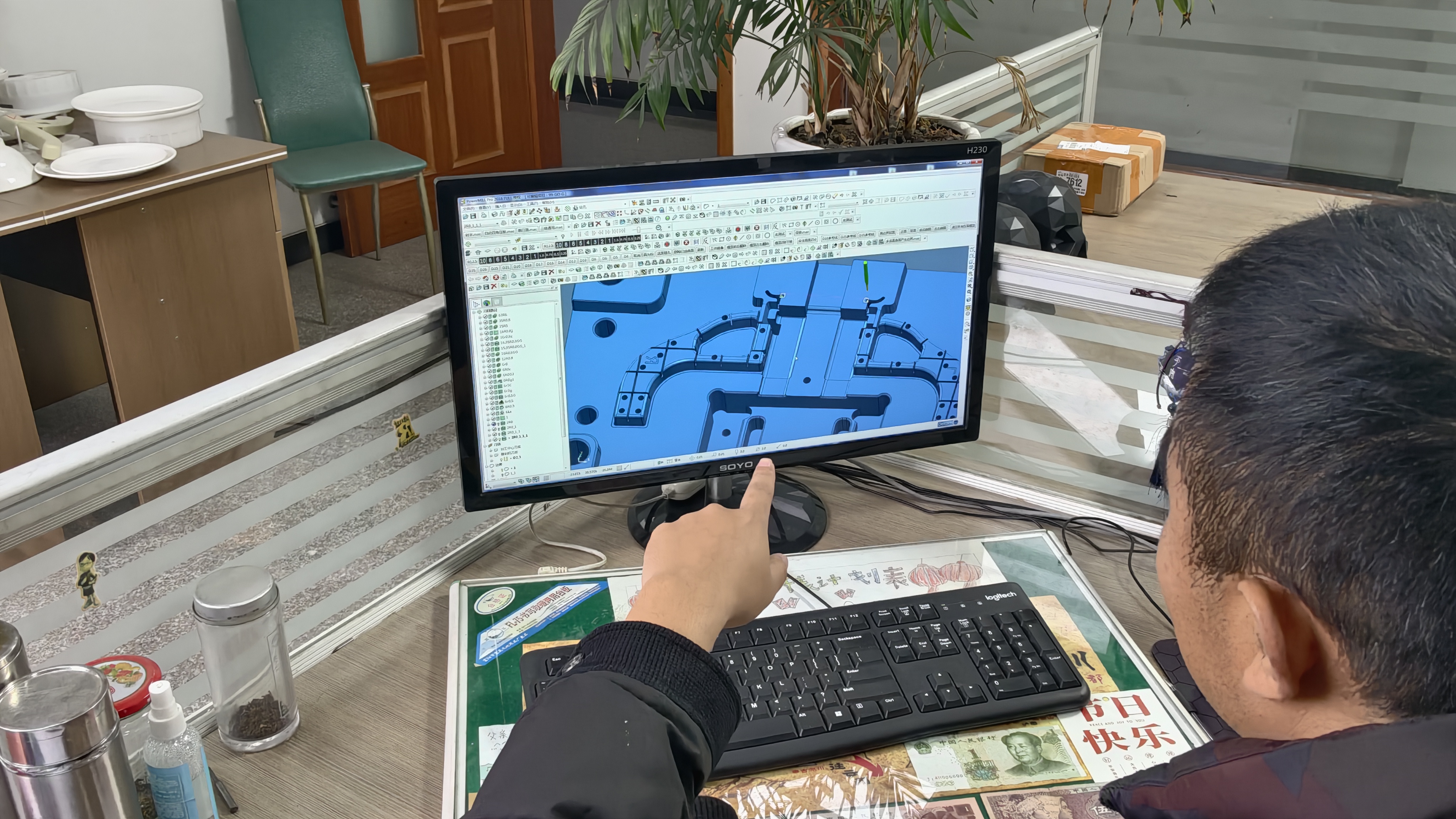

At Ningbo Chenshen Plastic Industry, we specialize in helping international partners navigate this complex transition. Our Yuyao-based facility is equipped with high-tonnage Haitian injection molding machines and a dedicated in-house tooling team that excels in DFM for the automotive sector. From initial metal-to-plastic feasibility studies to final Class-A surface finishing, we provide the technical transparency global buyers demand.

Ready to Start Your Conversion Project?

Connect with our engineering team for a feasibility audit and a competitive quote.

Post time: Jan-09-2026