In the fast-evolving automotive industry, lightweight plastic components are essential for improving fuel efficiency and performance. Reverse engineering plays a critical role in replicating and optimizing these parts when original designs are unavailable.

What Is Reverse Engineering in Automotive Injection Molding?

Reverse engineering automotive plastic parts involves taking an existing physical component—such as a dashboard, grille, or door handle—and digitally recreating its design when original CAD files are unavailable.

The process typically includes:

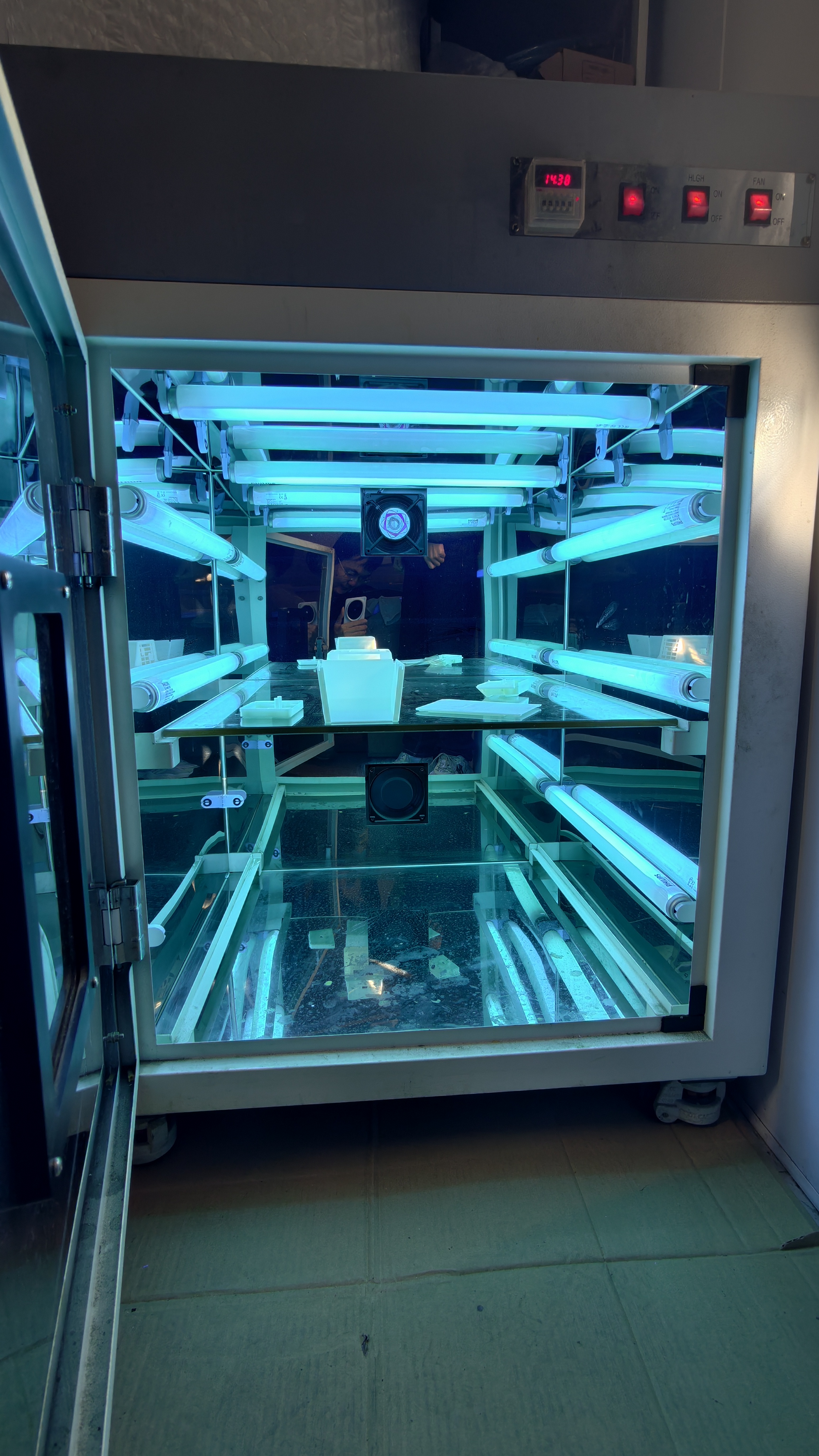

- 3D scanning the physical part to capture precise geometry.

- Reconstructing a parametric CAD model from the scan data.

- Accounting for material shrinkage, warpage, and tolerances.

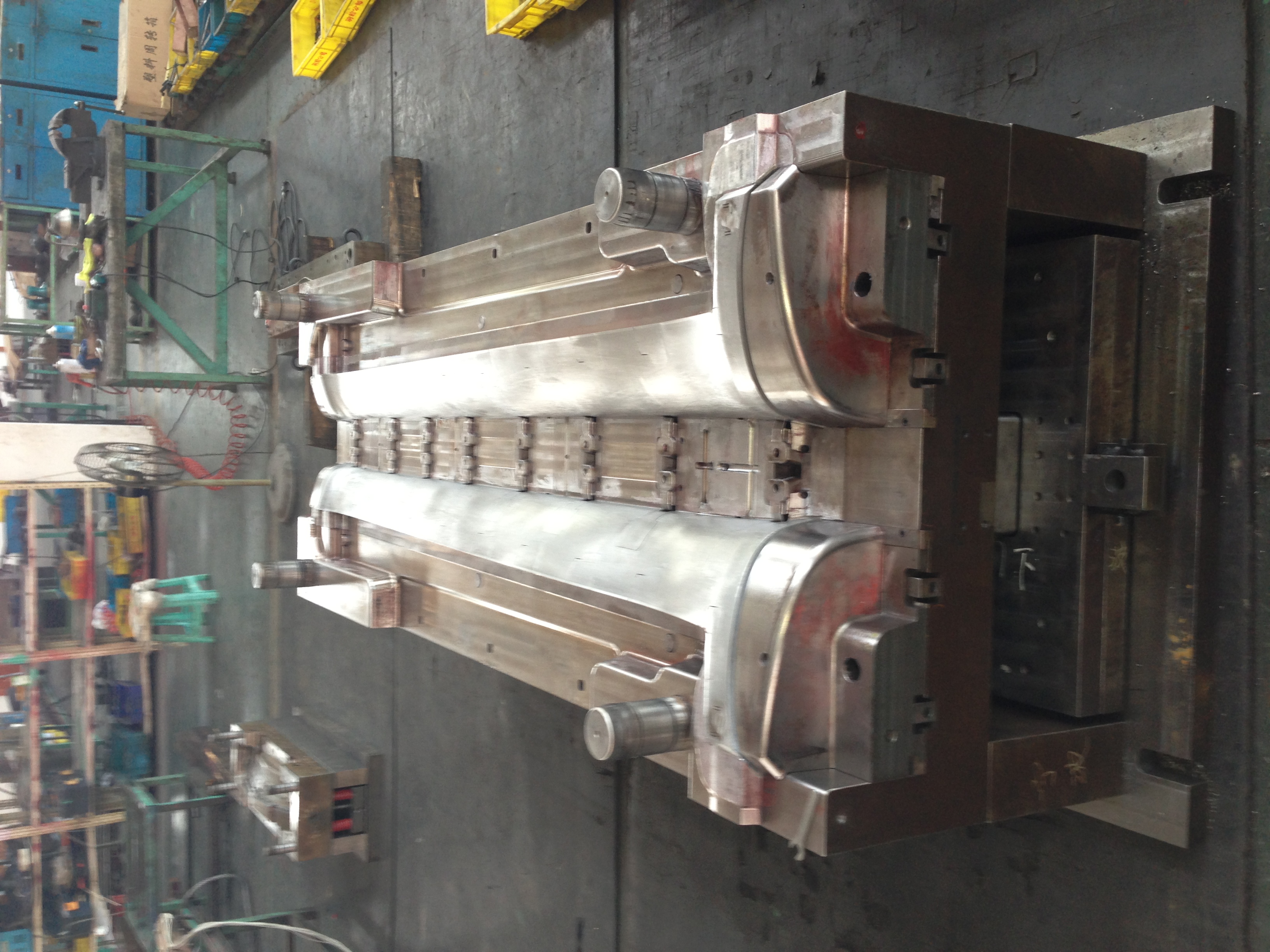

- Designing and manufacturing a new high-precision mold.

Top Benefits of Reverse Engineering for Automotive Plastic Parts

Cost Reduction and Faster Time-to-Market

Reverse engineering eliminates the need for full redesigns, reducing engineering hours and prototyping costs by up to 50%. New molds can be ready in weeks, accelerating production for tight deadlines.

Replication of Legacy and Discontinued Parts

Essential for classic cars or fleet maintenance, it ensures uninterrupted supply of discontinued components like grilles and dashboards.

Weight Reduction and Improved Fuel Efficiency

Optimize designs to replace metal with lightweight plastics, contributing to better MPG and extended EV range.

Design Optimization and Defect Prevention

Adjust geometries using simulation tools to eliminate warpage, sink marks, and other defects before production.

Enhanced Quality and Precision

Achieve sub-millimeter accuracy for safety-critical parts, ensuring perfect fit and compliance with automotive standards.

Sustainability and Material Innovation

Adapt designs for recycled or bio-based plastics, supporting eco-friendly automotive manufacturing.

Real-World Examples in the Automotive Industry

Manufacturers successfully use reverse engineering for EV dashboard conversions, aftermarket grille customization, and fleet door handle production.

How Ningbo Chenshen Plastic Industry Can Help

As a leading injection molding expert, Ningbo Chenshen Plastic Industry offers comprehensive reverse engineering services with advanced 3D scanning, CAD reconstruction, and precision mold manufacturing for automotive components.

Whether you need dashboards, grilles, handles, or custom parts, we deliver reliable, high-quality solutions.

Partner with Ningbo Chenshen Plastic Industry to unlock the full potential of reverse engineering in your automotive projects. Get in touch now!

Post time: Dec-21-2025